Roller Compacted Concrete (RCC) was once a niche paving system primarily used in military construction projects, but in the last five years RCC applications have emerged and the market opportunities for RCC have grown significantly.

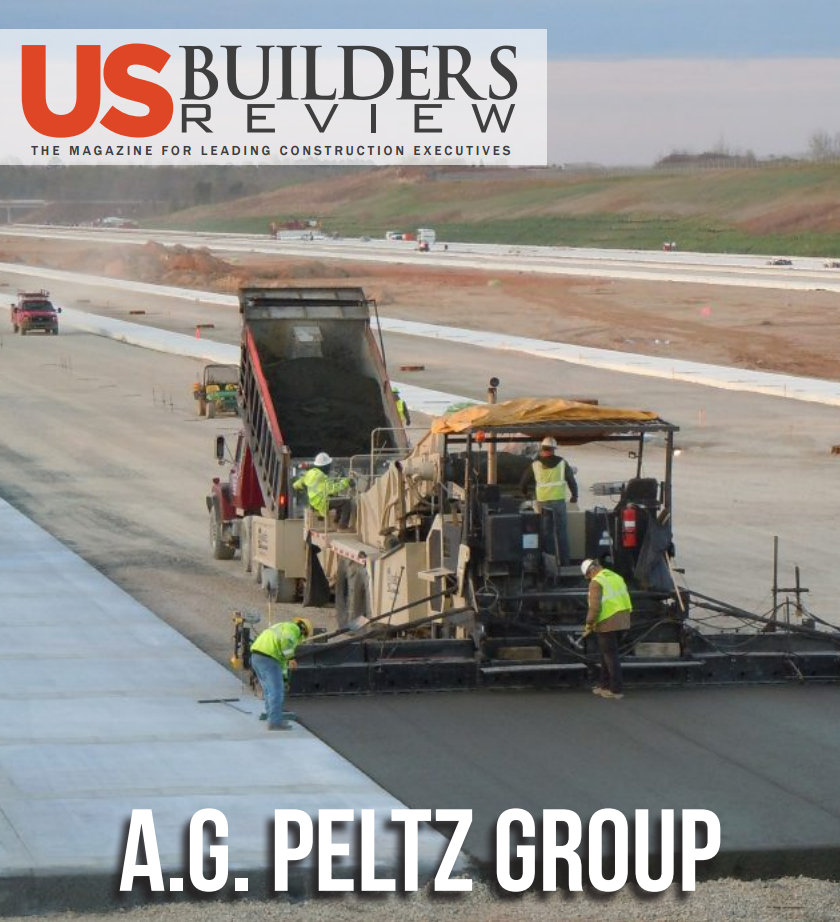

RCC is made of the same basic ingredients as conventional concrete – cement, water and aggregates – but unlike conventional concrete, the drier mix is stiff enough to be compacted by vibratory rollers. RCC needs neither forms nor finishing and it can be constructed with or without joints, making it a fast and economical option. A.G. Peltz Group, based in Irondale, Alabama, is a leader in the emerging RCC (roller compacted concrete) market.

Since inception, A.G. Peltz has completed more than 7 million square yards of RCC pavement on major projects throughout the U.S. and Mexico, making the company a leader in the RCC market. “We’re a nomad paving contractor, specializing in roller compacted concrete, soil cement, cement treated bases and pervious pavements, for the heavy industrial and intermodal market. Our primary market area is in the Southeast with over 90 percent of our business between Texas and Virginia,” says Chris Carwie, business development manager of A.G. Peltz. “A.G. Peltz is the largest RCC paving contractor in the U.S.”

Leading experience paves the way

US Builders Review – A.G. Peltz Group – Rolling out new applications for RCC throughout the Southeast

After purchasing the paving assets of Peltz Construction, Will Gray and Greg Abramson launched A.G. Peltz in 1999. The ownership and upper management of A.G. Peltz have a combined 50 years of experience in the placement of concrete pavements. This team includes Will Gray, managing and founding partner, Dan Vipperman, quality control manager and professional engineer, Tom Benacquisto, operations manager and site superintendent, and Chris Carwie, business development manager.

“The RCC market is growing rapidly,” Chris Carwie – Business Development Manager

As the RCC market continues to grow, A.G. Peltz is moving in stride, setting the bar for quality RCC applications. A.G. Peltz team members have been instrumental in writing and updating the new American Concrete Paving Associations (ACPA) RCC Specifications, the Portland Cement Association (PCA) RCC Pavement Specifications and have taken part in various national committees, including ACI327 Roller Compacted Concrete Pavements and the National Concrete Pavement Technology Center.

“The roller compacted concrete market is growing rapidly,” says Carwie. “There are a few driving factors that have really contributed to this growth – one being that the roller compacted cncrete product has improved; surfaces textures are better, along with equipment and placing methods. Second, the price of asphalt has increased resulting in RCC being more economical and third, the quality of RCC contractors has improved and more companies are providing quality workmanship.

“A quality RCC paving project will result in end-user satisfaction and lead to future opportunities. ”

With many other companies jumping on the RCC bandwagon, Carwie says end users must be especially sensitive to ensuring that they hire a quality contractor. “It takes a lot of time learned expertise to do RCC the right way,” he explains. “There are some companies doing it haphazardly, but the companies who are leading the market have the knowledge, the trained personnel and the equipment to provide quality paving projects.”

In 2007, A.G. Peltz rolled its leading experience into a consulting arm, called A.G. Peltz System Solutions. “This side of the business helps customers from start to finish, from preparing design submittals to curing in-place concrete,” says Carwie. “Even though we recognize that we are training our potential future competition in many cases, we believe it crucial that RCC is placed correctly. Ultimately, this saves customers time and money, keeping projects on schedule and reducing risk. Furthermore, a quality paving project will result in end-user satisfaction and lead to future opportunities. ”

Realizing the RCC benefits

In conjunction with A.G. Peltz Solutions, A.G. Peltz has delivered a range of roller compacted concrete applications. The company’s list of clients includes major names such as Kansas City Southern Railroad, Lowes, the Virginia Port Authority, the Houston Port Authority, APM-Maersk, Honda Manufacturing, Hibbetts Sports, Hyundai, Mercedes-Benz, ThyssenKrupp Steel, the Georgia Department of Transportation, the South Carolina Department of Transportation, the Army Corps of Engineers and many more.

At the new Hibbett Sports Distribution Center near Alabaster, Alabama, RCC was the choice application over traditional asphalt due to pricing and long-term performance expectations. A.G. Peltz placed more than 62,000 square yards and 12,000 cubic yards of 7-inch RCC. The RCC was placed at 30-foot pavement lanes with control joints sawed at 15-foot intervals. “It took us approximately four weeks to complete this job,” adds Carwie.

At the Charlotte International Airport, A.G. Peltz mixed and placed more than 275,000 square yards of RCC for the container stacking, loading and entry/exit areas adjacent to the Charlotte Airport. “The surface texture of our mix was considered excellent, with no visible segregation or loose material; something that’s quite difficult to achieve with RCC,” says Carwie. The CRIF Project was honored at the ACPA National Convention as the inaugural Gold Award winner in the Roller Compacted Concrete Paving category.

RCC has long been utilized by the military market.

In February 2014 at a project in Fort Campbell, Kentucky, A.G. Peltz worked with the USACE to place more than 45,000 square yards of 8-inch RCC pavement. RCC was placed at 25- to 30-foot pavement lanes with control joints at 12.5 to15-foot intervals. A.G. Peltz partnered with the USACE to review and modernize the existing specifications and the result was a cost-effective, quality multiway RCC application. RCC offers many benefits over traditional concrete as a durable, economical and environmentally-friendly application; in some cases, RCC can even achieve LEED credits not accessible with bituminous pavements. A.G. Peltz is showcasing all of the superior strengths of RCC. “The market is only going to grow more,” says Carwie. “We will continue to be a leader and seek more diverse applications for RCC.”